2022-07-04

Two production methods of frp grating: Molded frp grating & pultruded frp grating. Following is the difference of frp grating:

Molded FRP grating consists of continuous glass strands encased in resin and wrapped in a surfacing veil which protects the fibers and allows resin to saturate the outermost part of the bar as well as penetrate between the glass fibers. This ensures a smooth and corrosion-resistant surface, with a higher glass/resin ratio than molded products. The individual bars are then assembled using two-piece cross bars and epoxy to mechanically join the load bars.

Pultruded grating has unidirectional strength, with its much higher glass content resulting in a greater span capability than molded products. This product is usually specified in applications requiring larger spans or heavier loading.

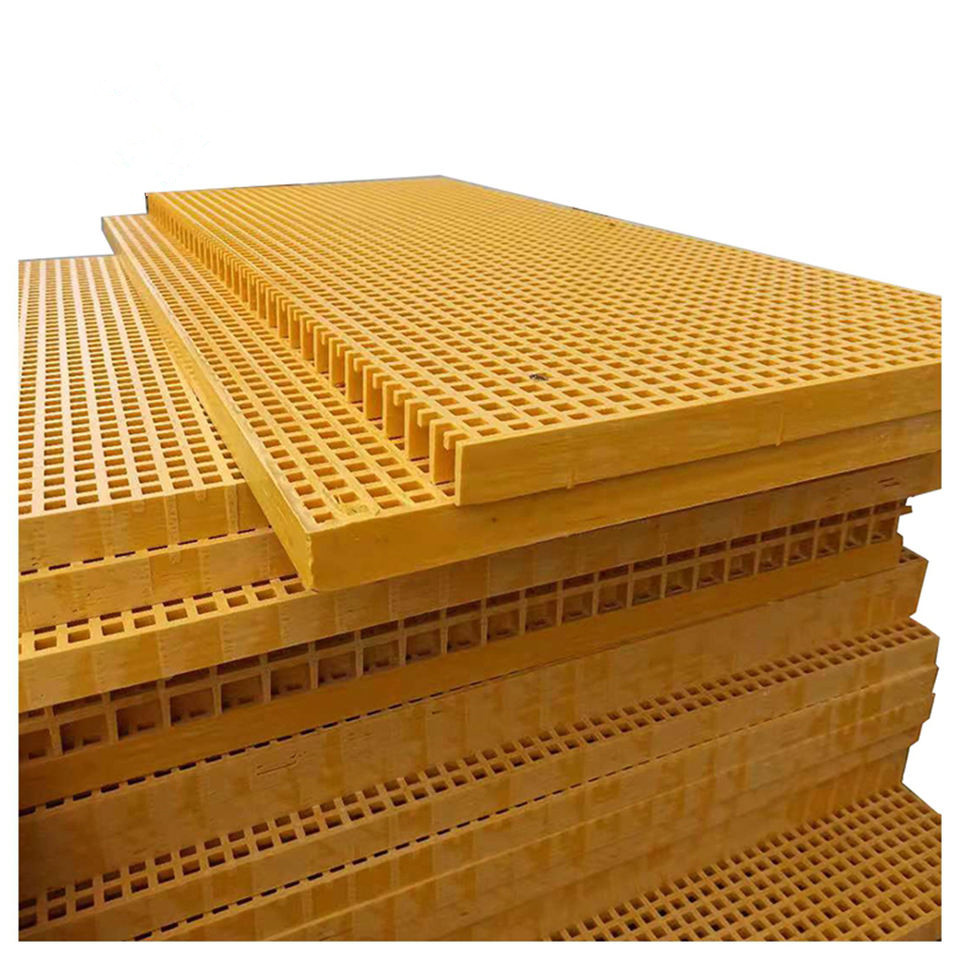

Molded grating process:

Molded grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and thoroughly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave) top surface. Any process such as post applied grit could be bonded after as a secondary operation. This continuous process produces an integral, one piece panel, which offers excellent corrosion resistance as well as bi-directional strength.

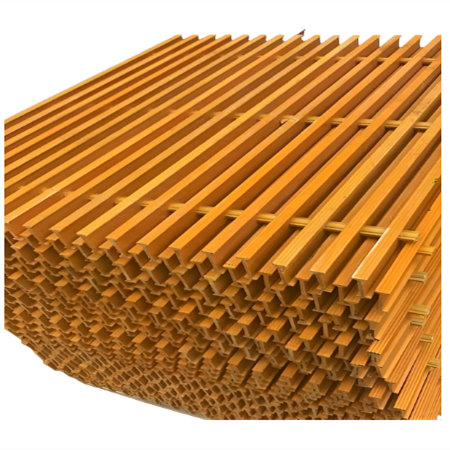

Pultruded grating process:

Fiberglass Reinforced Plastic (FRP) Pultruded frp grating is a kind of plank with interstice, assembled by FRP, produced its bearings to look as “H-section” or “T-section” and connected bearing by round rod of FRP. Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with constant cross-sections. Raw materials are a liquid resin mixture (containing resin, fillers and specialized additives) and flexible textile reinforcing fibers. The process involves pulling these raw materials (rather than pushing, as is the case in extrusion) through a heated steel forming die using a continuous pulling device.

So you can choose grating according to your needs. If you have any questions, please contact us at any time.

Whatsapp/Wehcat: 8618031887487, Email: anna@zhengnacn.com

Hebei Zhenana Welcome to your inquiry.

Anna

Tel:+8618031887487

Fax:+86 18031887487

Mobile Phone:+8618031887487

Email: anna@zhengnacn.com admin@zhengnacn.com

Address: Hengshui city, Hebei province

Related Products List

Anna

What can I do for you?